Prototyping & Testing

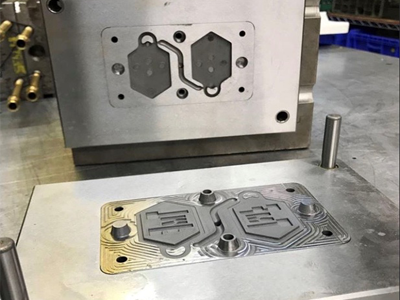

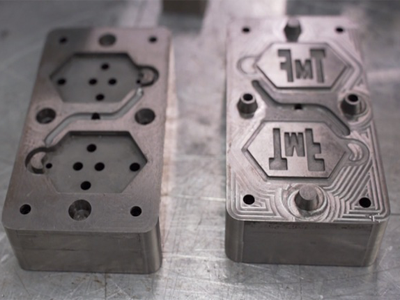

TMF will support the design process with a variety of Rapid Prototyping options for Design Evaluation and Testing. TMF has in-house Plastic 3D FDM Printing capability as well as the latest Metal 3D Printing process, using Stainless Steel or H13 tool steel filaments. CNC machining is still a good option for some prototype requirements. Here’s an example of a mold with Metal 3D Printed Cavity and Core Inserts in a MUD unit. The Inserts are equivalent to hardened tool steel which are conventionally made and can produce medium volume runs if required.

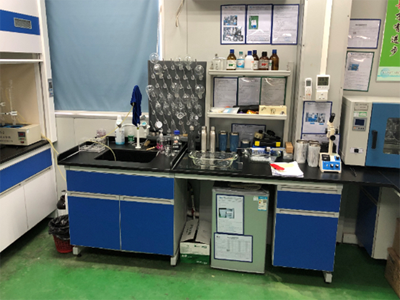

A variety of tests can be conducted for Components and Assembled products, from basic drop tests to accelerated Life and Environmental tests. TMF also has an in-house Lab in China capable of carrying out FDA and Prop 65 Regulatory Testing. The Lab will also work with a variety of third-party Globally Recognized Labs to provide supporting documentation and validation of materials used.